Inspection Equipment

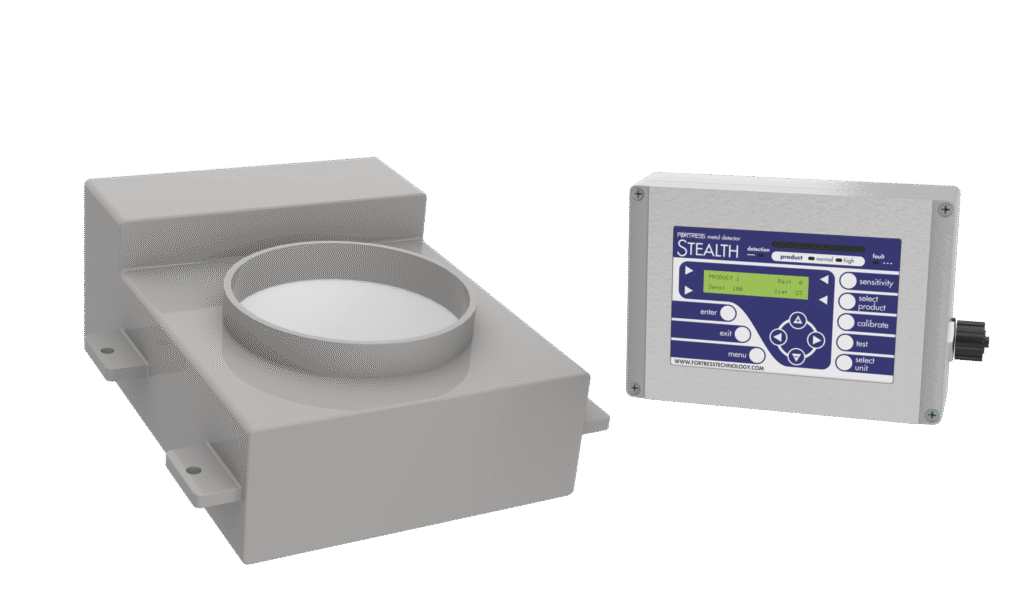

The Stealth Pharmaceutical Metal Detector provides the ideal solution for detecting and rejecting the smallest metal contaminants in tablets and capsules.

The Stealth Vent Tube Metal Detector is primarily designed to detect any fallen vent tube and fill tube nozzles in plastic or glass bottles of up to 3 liters/6.5 pints.

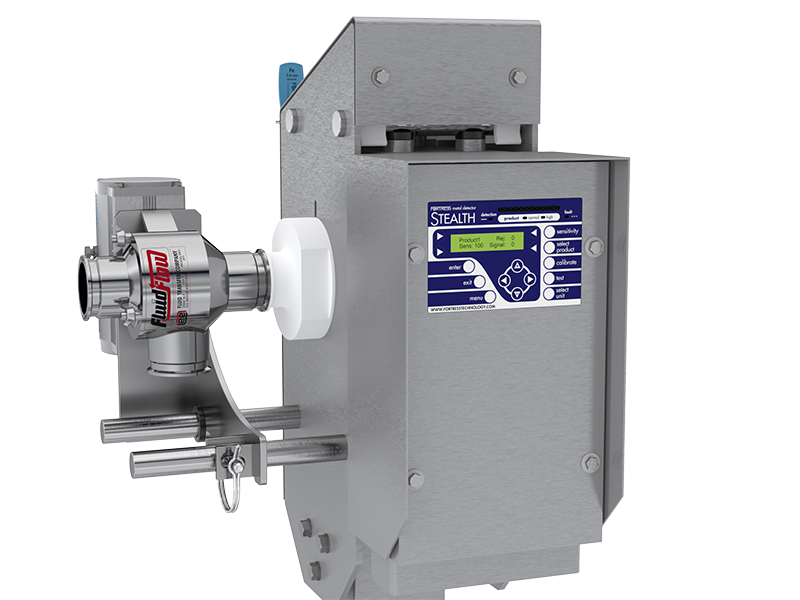

Pipeline Systems are manufactured to inspect the inline of pumped liquids and pastes transported through a pipe. Various valves, pipe materials, and fittings are available to suit existing lines and product specifications.

Ultra-slim Stealth Vertex Metal Detectors are used in specialized packaging applications involving free-falling products. The compact Vertex fits where other metal detectors can’t.

Meat products naturally have a high risk of containing metal fragments, which is why Fortress Technology developed the Meat Pump Metal Detection System to fulfill the highest quality standards of the food industry.

The Stealth Multi-Aperture Metal Detector is a compact system that fulfills all performance specifications and cuts the equipment footprint by over 50%, optimising floor space.

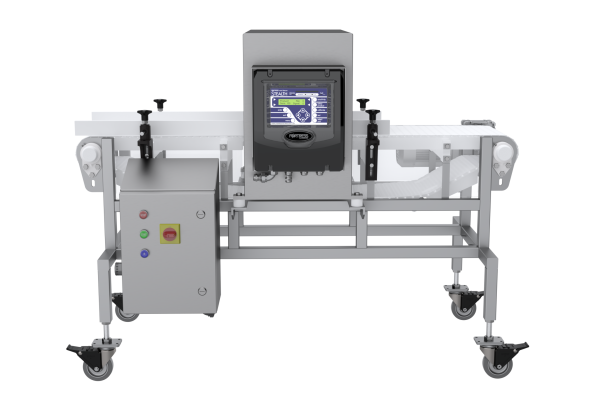

Vector Conveyor Systems are Fortress Technology’s standardised conveyor design and are custom manufactured to meet the end user’s needs and the unique application with shorter lead times.

The roll-around Stealth Laboratory Metal Detector Systems are used offline to examine rejected products further. The Lab unit lets you quickly separate metal contaminants from the defective product for further analysis.

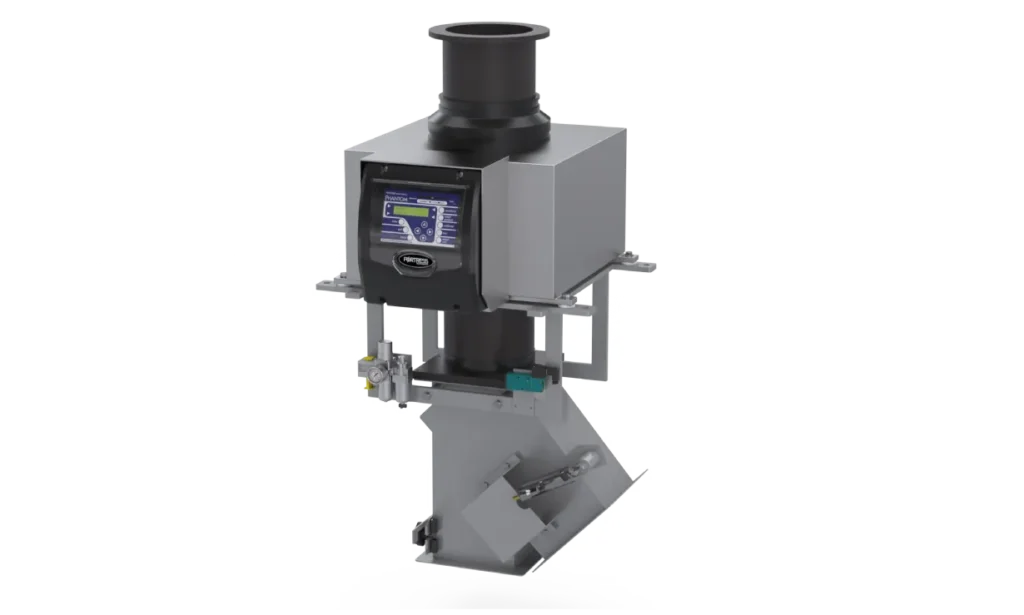

Stealth Gravity Metal Detectors are designed to inspect a wide range of products in free-falling applications. Systems are available with a selection of pipe sizes and reject systems to remove contaminated products from good product flow.

The Raptor is a highly accurate, fully integrated checkweighing and metal detection combination system designed explicitly for high-care food production environments.